fischer's steel fastening system allows for the creation of customized structures of any size and slope, ensuring the stability and durability of the installation.

The wide variety of available rails allows for the creation of structures to fasten multiple rows of panels with variable inclinations. Hot-dip galvanized components and stainless steel within the range provide resistance to weather and corrosion.

High-performance rails, connecting brackets, and hot-dip galvanized cantilever brackets are designed to stand the test of time, ensuring maximum stability for the installation.

Discover all of fischer's solar panels mounting systems.

In the case of low-loadable roofs, the hot-dip galvanized and stainless steel elements can be fixed directly to the structure thanks to the appropriate fixings.

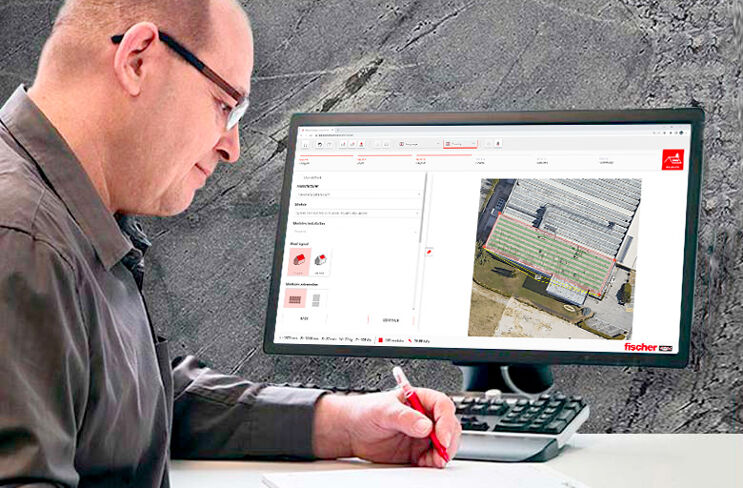

SOLARPANEL-FIX is an Online module of the FiXperience Suite for the design of mounting systems for photovoltaic panels: it supports professionals in the design of the photovoltaic substructure through a clear and logical flow.

The software allows to automatically calculate the actions of snow and wind loads through the geolocation of the construction site, according to the requirements of the European Standard EN 1991 (Eurocode 1). In addition, it allows to download the bill of materials to create the substructure, the installation plan and a technical report. The latter outlines the structurl checks of the system parts, according to the European Standards EN 1993 (Eurocode 3), EN 1999 (Eurocode 9) and according to fischer specifications.